Stainless Steel 310/310S Flanges Manufacturers

Stainless Steel 310/310S Flanges Manufacturers

Blog Article

Meta Aerospace is one name to reckon with when it comes to providing high-quality Stainless Steel 310/310S Flanges to industrial users all around the world. Precision and durability are given utmost importance in manufacturing these flanges, making them suitable for high-temperature and corrosive service conditions. Boasting high tensile strength, corrosion resistance, and oxidation stability, Stainless Steel 310 and 310S flanges are designed to function under extreme conditions and are thus one popular choice among many sectors.

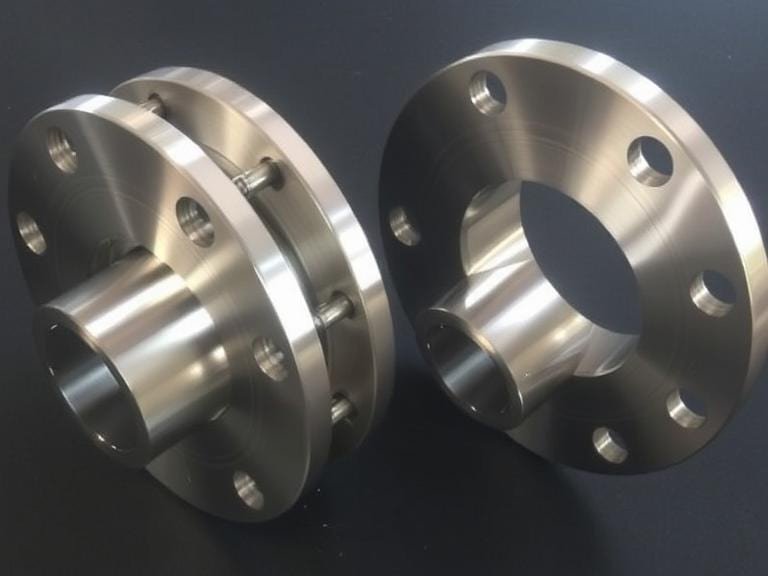

Stainless Steel 310/310S Flanges Suppliers like Meta Aerospace provide this material in various types like Weld Neck Flanges, Slip-On Flanges, Blind Flanges, Threaded Flanges, and Socket Weld Flanges. Stainless Steel 310 is an austenitic chromium-nickel steel with high oxidation resistance and high-temperature tensile properties. Stainless Steel 310S is a low-carbon version of 310 with better weldability and less chance of carbon precipitation when being welded or soldered. Both grades are well suited to pressure vessels, heat exchangers, furnaces, and more.

So, what are Stainless Steel 310/310S Flanges exactly? They are mechanical fittings that connect pipe, valve, pump, and other equipment in a piping system. They provide easy access to clean, inspect, or make modifications and are bolted together with gaskets to create a seal. Stainless Steel 310/310S flanges are notable owing to its resistance to oxidation and scaling up to 1100°C in steady service and 1035°C in intermittent service. Their superior level of chromium and nickel content further increases the resistance to corrosion and makes them extremely reliable under extreme industrial conditions.

One of the significant positives of Stainless Steel 310/310S Flanges is that they maintain strength and toughness properties when operating in high-temperature conditions. They are not magnetic when in the annealed state and have superior mechanical properties. They are extremely resistant to carburization, sulfidation, and general high-temperature corrosion. Another advantage offered by Stainless Steel 310S is better creep resistance and improved weldability that is very important in several fabrication operations.

Uses and Applications Stainless Steel 310/310S Flanges?

The flanges are suitable for operations demanding longevity, leakage-proof joints, and resistance to corrosive media. They are reliable and maintain structure under highly acidic or basic conditions too.

- In the oil and gas sector, these flanges are used in high pressure piping and offshore rigs.

- In the petrochemical and chemical sector, these flanges are appreciated for withstanding corrosive chemicals and solvents.

- In the power generation sector, the flanges are used in steam turbines and heat exchangers owing to temperature withstanding capabilities.

- In the pharmaceutical and food processing sector, the hygienic qualities are important in SS 304/304L flanges.

- In marine application too, these flanges are an important part of the system with superior performance in saltwater environments.

- In the automotive and aerospace markets, these are used in engine parts and exhaust systems where strength and corrosion resistance are paramount.